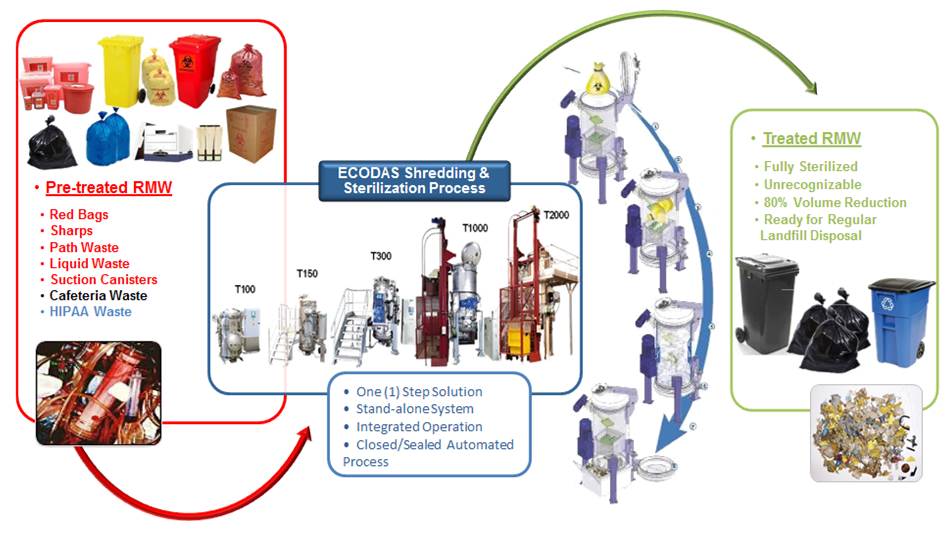

The ECODAS sterilizers are designed to neutralize the infectious waste, reduce its volume, and render its components unrecognizable and safe to dispose of as harmless municipal waste. All is done in one processing step and in a fully enclosed automated system.

The ECODAS technology is a patented process that is based on advanced GREEN autoclaving (non-burning) method that uses clean heated pressurized steam with no added chemicals to treat and dispose of the medical waste.

Our Technology

The treatment process combines internal shredding, direct heated steam, and high pressure to achieve complete sterilization of infectious materials.

|

|

|

6. Cooling

7. Draining

8. Vacuum

9. unloading

|

The system is required to treat and neutralize any waste that is listed as Regulated Medical Waste (RMW) , also known as Infectious Waste, Biomedical Waste, Bio-Hazardous waste, or “Red Bags.” This medical waste category includes:

- Biomedical waste that includes cultures and stocks

- Pathological and anatomical waste

- Sharps

- Animal waste

- Liquid and laboratory waste

The ECODAS process shreds internally the biomedical waste then automatically subjects it to a minimum temperature of 138°C / 280F and to a minimum pressure of 3.5Bars / 55psi of direct steam (Microbial inactivation of 8log10). The ECODAS sterilizers also reduce the volume of medical waste by 80%, and render its components unrecognizable. The final neutralized waste is safe for disposal as ordinary municipal waste.

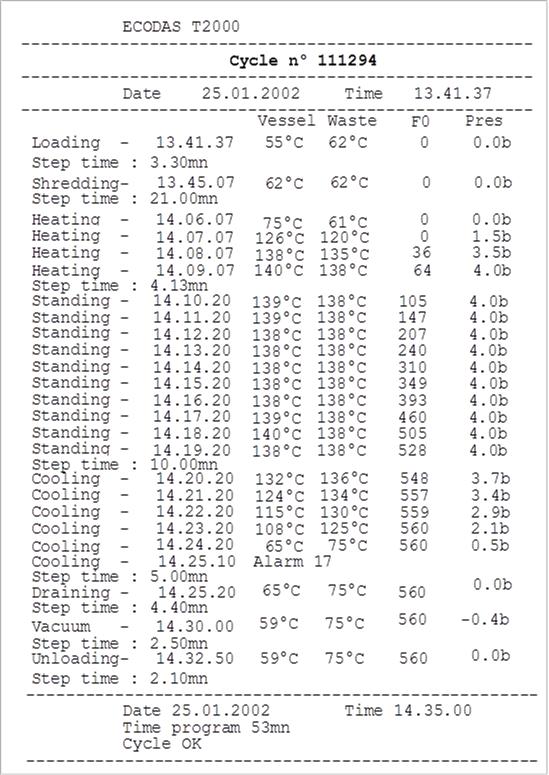

The whole operations and sequences of the ECODAS SYSTEM are entirely computerized and regularly controlled by an advanced programmable microprocessor offering reliable, simple, consistent, and safe treatment process. This Programmable Logic Controller (PLC) monitors, regulates, and maintains the operating parameters during the entire length of each automated treatment cycle.

The ECODAS SYSTEM also features forward-thinking interactive design and diagnostic features via a Graphical User Interface (GUI) enabling the operator to interface effortlessly with the unit and follow commands to operate and maintain the system as well as to troubleshoot errors and repair anomalies. This highly-developed touch screen system also support cycle’s progress display, support, configuration, setup, maintenance, troubleshooting, alarms alert, and step-by-step diagnostics assistance.

The SYSTEM is fully automated and comprehensive allowing very minimum handling of medical waste, with NO contact with the infectious waste during the treatment cycle.

The ECODAS SYSTEM guarantees secure, safe, and reliable process by monitoring, recording, and safeguarding all operating characteristics and treatment data through password-protected protocols.

The ECODAS STERILIZER is equipped with advanced safety features that include the following:

- The ECODAS SYSTEM is a stand-alone machine that is equipped with unconventional interlock mechanisms and an exceptional shredder jamming and waste sticking prevention features.

The system is also equipped with a fail-safe built in technology with an alarm system for an instant and guided operator’s intervention.

The system is also equipped with a fail-safe built in technology with an alarm system for an instant and guided operator’s intervention.- The ECODAS SYSTEM automated and comprehensive treatment operation not only reduces the operator’s handling time to a minimum, but also eliminates the employee’s direct contact with the infectious waste during the entire treatment cycle.

- The ECODAS SYSTEM is outfitted with a secured control process that prevents operator from changing, bypassing, or overriding any treatment’s mechanisms, criteria, or parameters.

- For the highest quality and safety assurance, ECODAS pressurized vessel and its integrated shredder are entirely and ONLY made of stainless steel. The machine is completely sealed; No air, particulate, or liquid can be released/leaked during the treatment cycle.

The ECODAS SYSTEMS guarantees an improved RMW compliance and quality assurance due to the following advanced capabilities:

- Built-in security features guaranteeing that all treatment conditions are achieved prior unlocking and opening the system’s unloading door to release the treated waste. Temperature, pressure, and exposure time are continuously monitored and maintained throughout the computerized process.

- Database and information security are guaranteed through password protected programs that confirm the integrity, the validity, and the protection of the operating process/parameters.

- For each treatment cycle, the operating results of essential data parameters are automatically printed, digitally stored, and securely protected for internal or external review.

- Recorded data include cycle number, treatment step, cycle ok status, and treatment parameters such as exposure time, chamber temperature, steam pressure, and waste temperature.

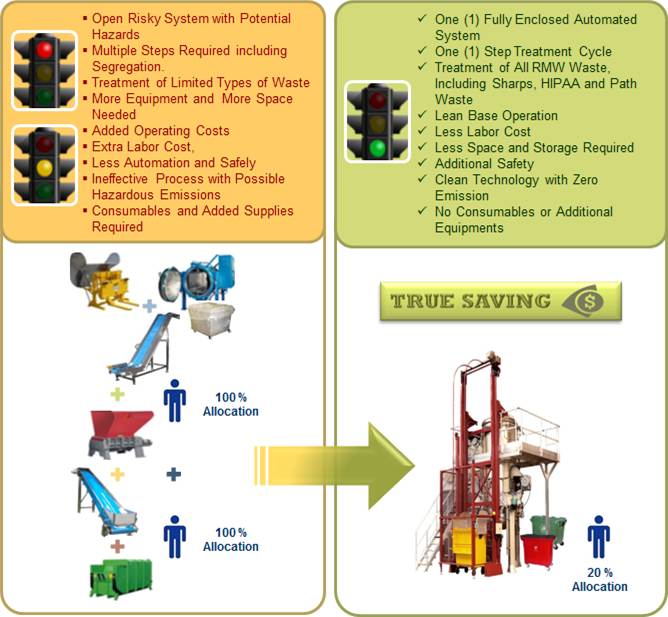

Unlike traditional autoclaving technologies where the steam does not penetrate thoroughly into the core of the waste bulk, ECODAS SYSTEM shreds the waste prior to the sterilization cycle directly exposing the inner waste contents to the saturated steam achieving a microbial inactivation of 8log10. The closed operating sequence of internal pre-shredding followed by a sterilization phase is critical to guarantee steam penetration and to ensure delivering an effective treatment process and true neutralization of all type of infectious waste stream.

The treatment process is completed in one step form load to unload circumventing any intermediate handling of the waste either manually or automatically through conveyance and other complementary equipment.

The ECODAS SYSTEM does not require any consumables (e.g. autoclavable bags, liners, chemical/disinfection products, packages, printing labels) or any supplementary equipment (e.g. autoclavable carts, conveyors, external shredder).

Risks and Limitations of Traditional Autoclaves

Since 1993 ECODAS has been designing, manufacturing, and supplying customers worldwide with automated solutions for medical waste treatment.

For more than twenty years ECODAS team has leveraged a wide expertise in designing and manufacturing of pressurized and automated thermal machines to provide high value medical waste treatment solutions and services using environmentally friendly technology.

Today, with more than 280 ECODAS SYSTEMS installed in more than 60 countries , ECODAS SYSTEMS are well known worldwide for superior performance in terms of safety, speed, durability, reliability, and flexibility while remaining cost effective.